Developing a resilient and diversified supply chain, Syngene works with over 2,800 suppliers across 30+ countries, ensuring strict quality and regulatory compliance while aligning with evolving sustainability expectations.

Syngene has committed to addressing Scope 3 emissions, which occur across our value chain and represent a significant portion of our total carbon footprint. Our goal is to ensure that 81.6% of our suppliers by emissions, specifically those involved in purchased goods and services, capital goods, and upstream transportation and distribution, have science-based targets in place by FY28.

of suppliers by emissions are committed to the Science Based Targets Initiative

Suppliers have signed the Supplier Code of Conduct

Sourcing within India

of our suppliers by spend have valid ESG assessment score cards

average score improvement as a result of supplier handholding

of our suppliers are compliant with our Anti-Bribery Anti-Corruption policy

We uphold rigorous standards of responsibility throughout our supply chain. To learn more about our policies, please visit:

Execution excellence to us means delivering with precision, listening actively, and improving continuously. At Syngene, excellence is a core value that shapes everything we do. Guided by this principle, we strive to create value and delight customers through strong project management, structured service delivery, and operational excellence.

We continue to drive efficiency and quality improvements through structured Lean and Six Sigma programs, where employees progress from White Belt (introductory level) to Yellow, Green, and Black Belt (advanced expertise).

White Belt

Yellow Belts

Green Belts

Black Belt

Basic Project Management

Advanced Project Management

Intermediate Project Management

Our cybersecurity framework is built on international best practices, aligned with the ISO 27001:2022 Information Security Management System (ISMS) and NIST Cybersecurity Framework (CSF). This alignment supports continuous improvement and positions us to respond effectively to evolving threats.

Project VEGA is Syngene’s enterprise-wide digital transformation initiative aimed at automating and integrating core business processes - from lead generation to revenue realization. By connecting systems like SAP, Salesforce, SynPro, CLM, and Ariba, VEGA enhances efficiency, reduces manual effort, and strengthens customer engagement. Phase 1 delivered ₹10 crore in savings through MRP adoption and inventory optimization. Additional modules like CLM and d-VEGA streamline contract workflows and lead management. Phase 2 focuses on establishing a Data Management Office to ensure data integrity and support the transition to SAP S/4HANA.

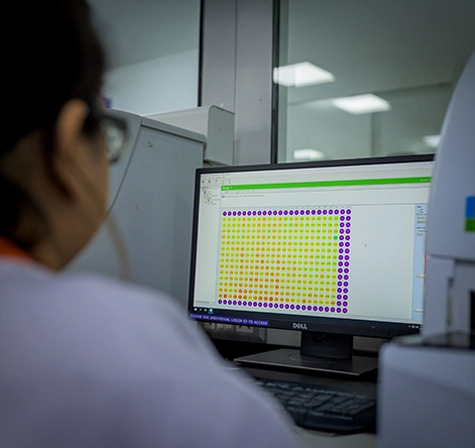

Our digital infrastructure underpins the security and reliability of our scientific and manufacturing services. We continue to adopt Industry 4.0 technologies that enable paperless operations, precision-driven data analytics, and automation-driven efficiency, all within a secure digital ecosystem.

Key digitization initiatives